Sep 21

Bold and delicate

manufacturing that is faithful to the basics

We can only realize with ceramics

We manufacture products with overwhelming advantages.

Altitude that only craftsmen can do, satisfying submicron accuracy

Please see the products manufactured by various technologies.

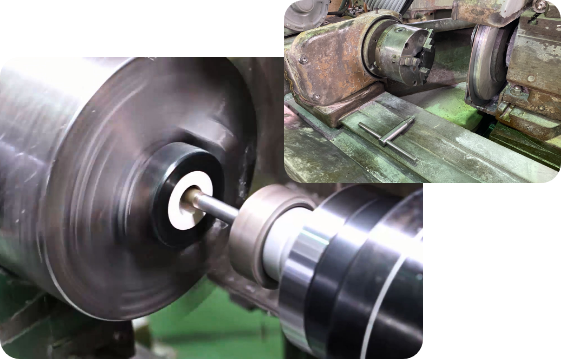

For precision processing of ceramics

Please leave it to Sanyu Tokusyu Seiko Co., Ltd.

Our company was founded in 1967 as a measuring gauge processing manufacturer.

The processing equipment started from the state of two.

Shortly after opening, we will start processing cemented carbide.

We have set a goal for difficult-to-cut materials in order to differentiate ourselves from others.

Products

Please see below for examples of ceramics applications.

Zirconia ceramics

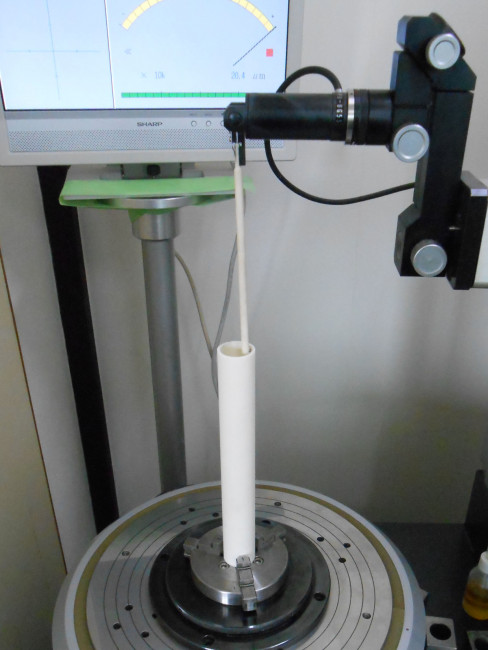

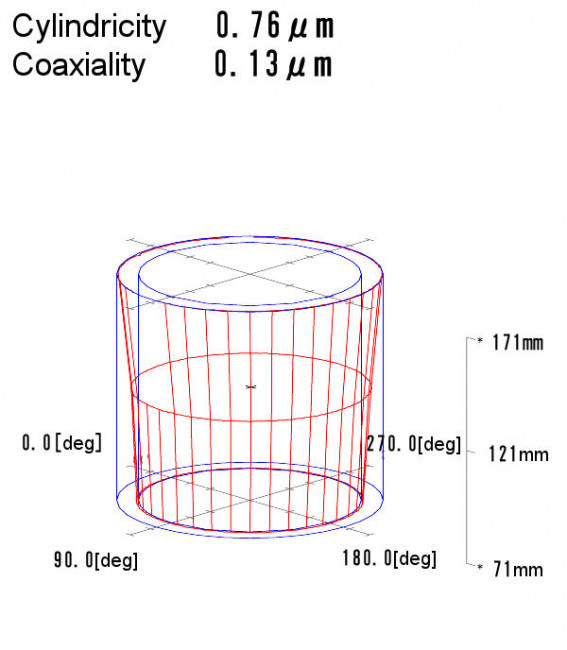

Cylindrical Pipe

This sample is made of zirconia ceramics, has an inner diameter of φ14 mm and a total length of 100 mm, and exceeds 7 when converted to an L / D ratio. The cylindricity of this pipe is 0.3 μm, which is extremely accurate.

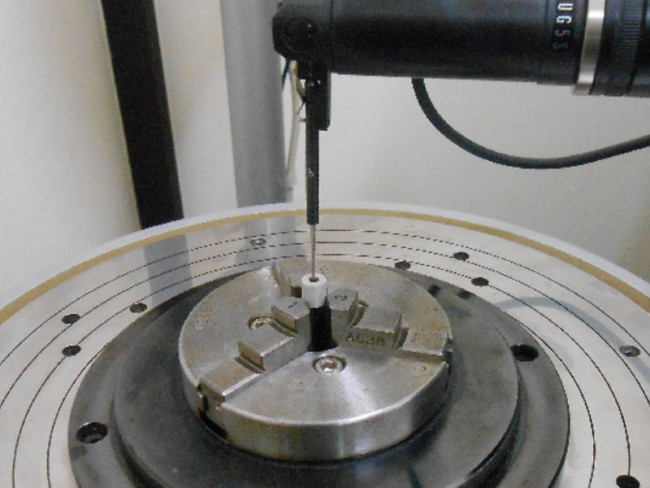

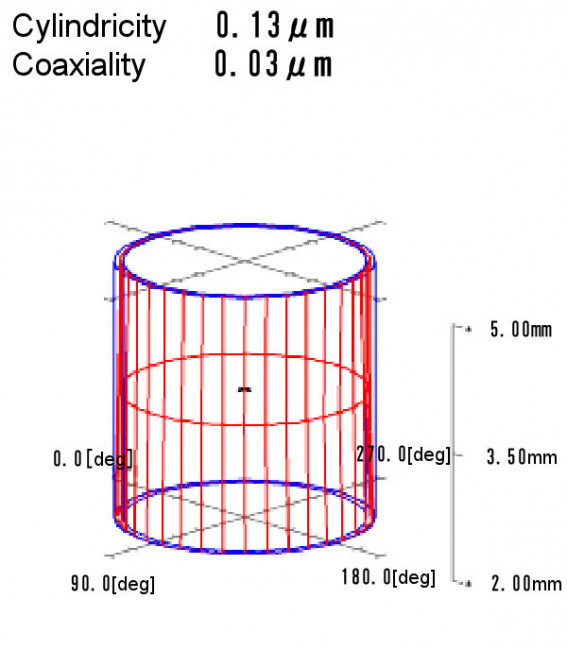

Silicon Nitride Ceramics

Thin-walled Pipe

This sample is made of silicon nitride and has a cylindrical shape with an inner diameter of about 2.5 mm and an inner diameter of φ30 mm and a total length of 40 mm. The cylindricity of the inner diameter is finished to 0.23 μm.

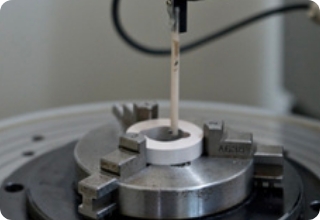

Zirconia ceramicsInner

diameter groove ring

In the case of ceramics, since electricity is not conducted, it is not possible to machine grooves by electric discharge machining. Even for such workpieces, we can accurately process the roundness of the inner diameter.

See details

Commitment

Our thoughts

With the times, customer needs have changed, and the products we manufacture have also changed.

I would like to continue to be involved in manufacturing that is useful to you.

It would be a great pleasure to know about our company through this website.

We sincerely hope that your needs will match our processing technology and that it will be useful.

See details

Concept

Difficulty of 1 μm

At our company, the average manufacturing tolerance of products such as jigs and tools was about 5 μm.

However, with the times, many products require gauge-level accuracy.

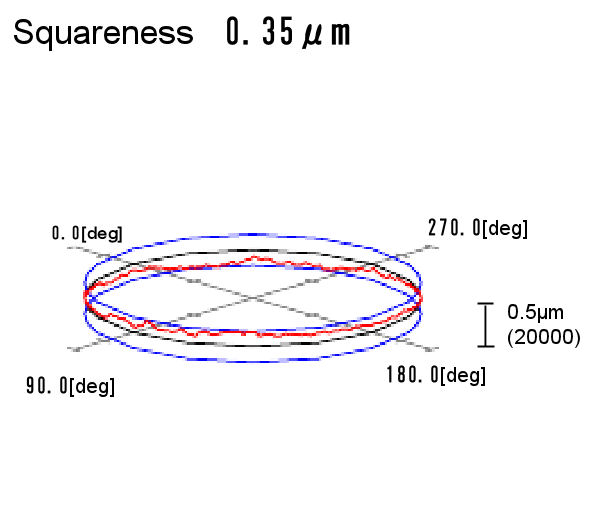

In addition to the absolute value, some products have roundness, straightness, runout of inner and outer diameters, and the squareness of the end face with respect to the inner diameter of 1 μm or less.

The number 1 μm changes even if you touch it with your bare hands or take a sigh.

A small amount of measurement error will occur.

Regarding the absolute dimensions, we pay close attention to the processing while matching the accuracy with the customer.

See details